-

Produits

Aperçu des solutions d'inspection CapWatcher Q-Line CapWatcher Compact CapWatcher B-Line CapWatcher SC CapWatcher FC Périphériques pour bouchons IntraOne BarrierWatcher

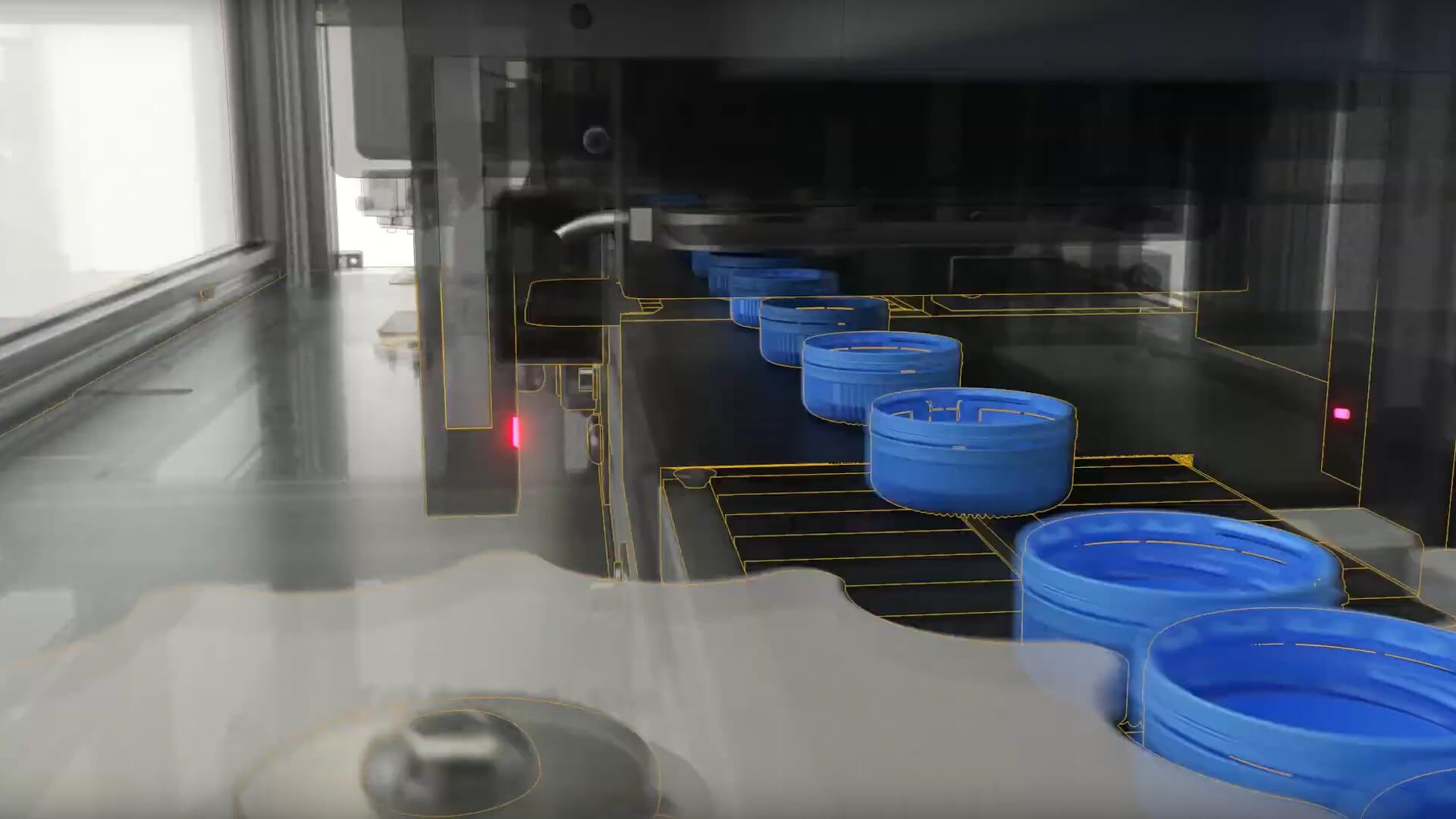

Êtes-vous prêts pour les bouchons attachés?

Nous le sommes.

Découvrez l'inspection des bouchons attachés avec notre CapWatcher Q-Line.

Aperçu des solutions de software IntraVision IntraVisualizer IntraRecommender Intelligence artificielleComment l’intelligence artificielle et le Deep Learning peuvent-ils être utilisés dans l’inspection par vision? Dans quelles applications est-il bénéfique?

- Industries

- Service

- Actualités & Blog

- A propos de nous

- Carrière

- Contact

Produits

Préformes

Industries

Aperçu des solutions d'inspection

PreMon

PreWatcher Offline

PreWatcher Inline

Sample-PreWatcher

LayerWatcher

ColorWatcher Lab

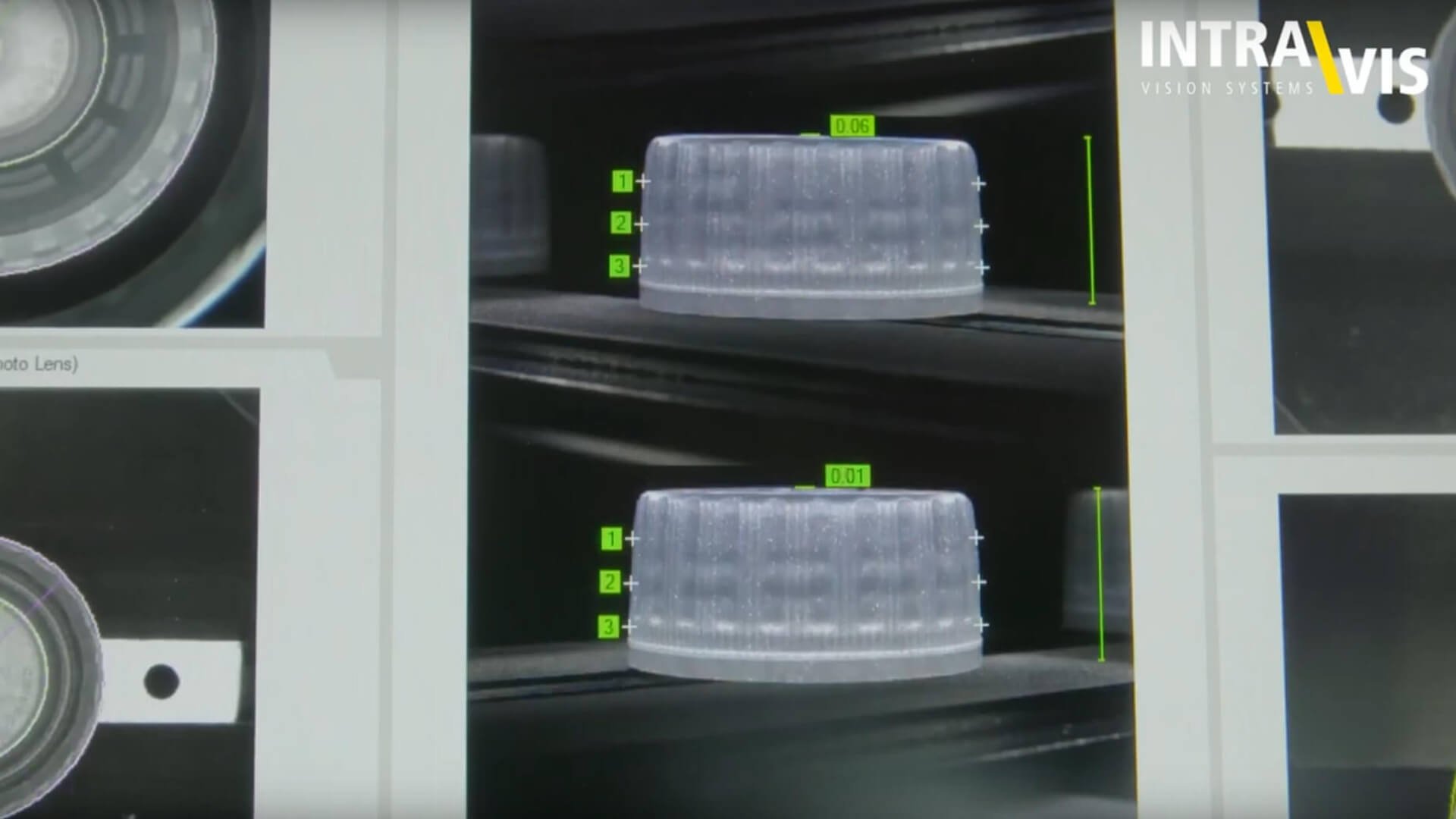

Bouchons

Aperçu des solutions d'inspection

CapWatcher Q-Line

CapWatcher Compact

CapWatcher B-Line

CapWatcher SC

CapWatcher FC

Périphériques pour bouchons

IntraOne

BarrierWatcher

Bouteilles & Contenants

Aperçu des solutions d'inspection

SpotWatcher Customized

SpotWatcher Basic

SpotWatcher Pharma

BarrierWatcher

IntraOne

Étiquetage

Couche barrière

Software

Alimentation & Boissons

Cosmétiques & Soins Personnels

Pharmacie & Médecine

Chimiques Ménagers & Industriels

Service

Actualités & Blog

A propos de nous

Carrière

Contact