Inspect safely - at any time

One thing is particularly important in quality control: reliability - not only internally, but also towards your own customers. Many companies have to prove the functionality of their inspection systems on a regular basis - whether out of their own responsibility or due to contractual requirements from major customers. With the new Validation Mode, we offer a powerful tool to ensure exactly that: documented, traceable and reliable validation of inspection processes.

What is the Validation Mode?

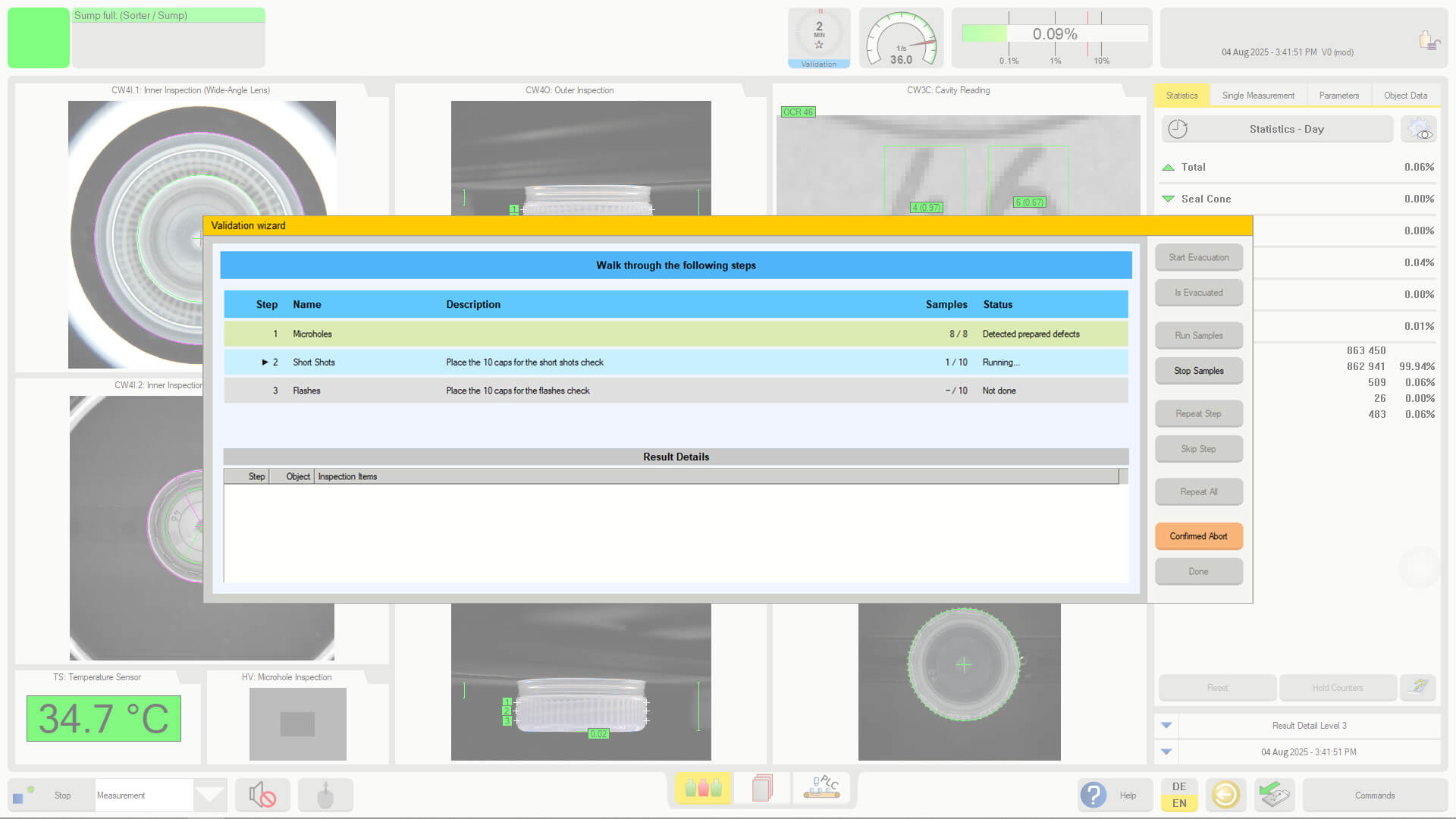

Validation Mode is a guided validation process that companies can use to regularly check whether their inspection system continues to reliably detect all relevant defects. A defined set of defect patterns is run through the system. Validation Mode guides you through the process step by step: it specifies which object is to be inspected with which specified defect, evaluates the results and only moves on to the next validation step when you are satisfied with the result - until all tests have been successfully completed.

Why is this important?

Our inspection systems are extremely stable and reliable. Nevertheless, operating errors can occur in practice - for example due to carelessness, inadequate training or time pressure. External influences such as contamination, temperature fluctuations or changes in the production environment can also affect the inspection accuracy and precision of a system. Validation Mode helps to identify and eliminate such risks at an early stage - before they have an impact on product quality.

Flexible, secure and integrated - this is how it works

- Various start options: Validation Mode can be started automatically after a defined time interval, after a certain number of checked objects, after a system start or manually at any time.

- Guided process: The mode guides the user through each validation step - including clear instructions and automatic result evaluation.

- Access control: Only authorized persons can complete the validation process. The authorization level and the classification of checks as critical or non-critical can be freely configured by you.

- Mandatory: If desired, the validation mode can be set so that the test system can only be used again once the validation process has been successfully completed.

- Plannable integration: A display informs you when the next validation is due. Validation can also be brought forward within a defined time window - ideal for integration into existing production or maintenance processes.

- Optional use: Validation mode is not a technical must - you can decide for yourself if and when you want to use it.

Added value for your production

- Regardless of which products are tested - Validation Mode offers clear advantages:

- Maximum process reliability: faulty tests are detected at an early stage and can be rectified.

- Documented quality: Every validation process can be logged and traced - ideal for audits and certifications.

- Confidence in the technology: Operators, quality assurance and management can rely on the test results of the test system - and can also prove this to their customers.

Conclusion: Quality you can rely on

With Validation Mode, we create an additional safety net for your production. It not only protects against human error and external influences, but also strengthens confidence in your automated testing processes - both internally and externally. Real added value for anyone who relies on uncompromising quality.