Step into Tomorrow: Cutting-edge Inspection Solutions at NPE

We are ready to showcase its huge range of solutions at this year's NPE, taking place May 6-10, 2024, in sunny Orlando, Florida. A total of six state-of-the-art quality control systems are brought to the forefront across four pivotal areas: Closures, bottles and containers, preforms as well as labels and decoration. Witness them live on-site at our booth and the booths of various partners. For a sneak peek before the start of the trade show, delve into the following article.

At Booth S15063, we are ready to excite visitors with two cutting-edge systems: A LabelWatcher 360° for the inspection of pressure-sensitive labels, and a SpotWatcher Customized for the quality control of bottles and containers. You are already familiar with these solutions? No way! Uncover initial insights about the further developments in the following two sections.

Breaking Boundaries with the LabelWatcher 360°

Be prepared for the game-changer in label inspection technology: A system for the 360° quality control of labels applied on both standard and uniquely shaped products, regardless of the rotational position of the products. Janina Orlowski, Head of Product Management and Marketing at INTRAVIS, highlights: “With the LabelWatcher 360°, we're pushing boundaries by inspecting even the most unconventional product shapes, elevating standards across the board. Inspecting a product with a square bottom and round top? This is easily possible with the sophisticated mix of adapted hardware and specialized software algorithms.”

Be prepared for the game-changer in label inspection technology: A system for the 360° quality control of labels applied on both standard and uniquely shaped products, regardless of the rotational position of the products. Janina Orlowski, Head of Product Management and Marketing at INTRAVIS, highlights: “With the LabelWatcher 360°, we're pushing boundaries by inspecting even the most unconventional product shapes, elevating standards across the board. Inspecting a product with a square bottom and round top? This is easily possible with the sophisticated mix of adapted hardware and specialized software algorithms.”

Apart from typical label quality inspections, the LabelWatcher 360° at NPE will also provide code reading and conduct various inspections at the bottle’s opening. Thanks to its user-friendly and easy-to-handle user interface and the assistance of the innovative Software Wizard known as “Assistant 360°”, setting up new products can be done in just a few simple steps by any machine operator.

Finally, the compact footprint of the LabelWatcher 360° is a distinctive feature. Its sleek design allows for a seamless integration at any point behind the labeling machine, ensuring a flexible and space-saving solution without any compromises.

Modern and efficient: SpotWatcher Customized in new Design

The SpotWatcher Customized is the second system showcased at our booth at NPE. It’s a well-known and reliable container inspection system which is highly regarded by many global players. Recently, it has been upgraded with a sleek Slash Design which will make its deput at NPE. Just a modern look? Not at all! Thanks to the innovative design, the SpotWatcher now boasts faster delivery times without compromising quality. Moreover, its modular profile frame and adaptable enclosure allow for easy adaptation to meet individual customer needs. This is particularly crucial in today’s rapidly evolving production landscape.

The SpotWatcher Customized is the second system showcased at our booth at NPE. It’s a well-known and reliable container inspection system which is highly regarded by many global players. Recently, it has been upgraded with a sleek Slash Design which will make its deput at NPE. Just a modern look? Not at all! Thanks to the innovative design, the SpotWatcher now boasts faster delivery times without compromising quality. Moreover, its modular profile frame and adaptable enclosure allow for easy adaptation to meet individual customer needs. This is particularly crucial in today’s rapidly evolving production landscape.

At the NPE, the SpotWatcher Customized offers a range of inspections for identifying material and contour defects, material inserts as well as color streaks. Moreover, the system measures the dimensions in the thread area. Visitors can witness these detailed inspections firsthand at our booth through daily presentations. Additionally, the INTRAVIS team will present the benefits of advanced software functionalities like such as person-based user administration, reject rate monitoring based on inspection criteria, and a long-term image memory.

Fastest closure inspection ever

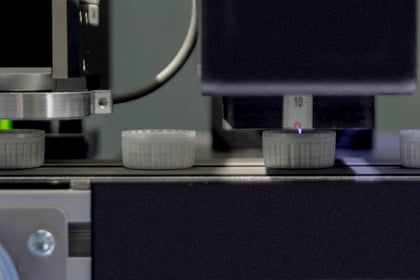

The advancements in vision inspection are not limited to bottles and containers as well as labeling. Stop by the booth of our partner Netstal Inc (W223). There, an upgraded inspection solution for plastic closures will be presented: The CapWatcher Q-Line has been optimized for even faster production environments. Unveiling this further development at NPE, the closure inspection system can now inspect up to 80 closures per second. This involves an all-round inspection of the closures for common defects and issues, including temperature measurement and contactless micro-hole inspection. In addition, the cavity number reading, paired with a cavity-related evaluation of the measurement results, allows customers to precisely localize potential for improvement and schedule their maintenance intervals with even greater precision.

The advancements in vision inspection are not limited to bottles and containers as well as labeling. Stop by the booth of our partner Netstal Inc (W223). There, an upgraded inspection solution for plastic closures will be presented: The CapWatcher Q-Line has been optimized for even faster production environments. Unveiling this further development at NPE, the closure inspection system can now inspect up to 80 closures per second. This involves an all-round inspection of the closures for common defects and issues, including temperature measurement and contactless micro-hole inspection. In addition, the cavity number reading, paired with a cavity-related evaluation of the measurement results, allows customers to precisely localize potential for improvement and schedule their maintenance intervals with even greater precision.

Experience the extremely fast, but precise performance of the CapWatcher Q-Line in action at NPE where it operates live behind a Netstal CAP-Line with a clamping force of 4500 kN, paired seamlessly with a CapLab from PackSys Global. Of course, the closures must also be sorted and fed, and octabins must be filled. Marius Pötting, Product Manager Caps & Closures at INTRAVIS, states how this is accomplished by INTRAVIS periphery for closure production lines: "Our Cooling Conveyor and CapFeeder ensure smooth sorting and feeding of the closures to the inspection system, while our AirDiverter fills the downstream octabins. Everything from a single source!"

The overall closure production setup is already thriving in American production halls. Marius Pötting elaborates: “What you can witness here is not just an exhibit for a trade show – It’s a glimpse into a real-world application. The complete solution shown on the Netstal booth with a 128-cavity mold and our downstream equipment is identical to those employed by a prominent US contract manufacturer. And it has already successfully proven its performance over months of rigorous operation.”

IML Pioneering in the Medical Industry

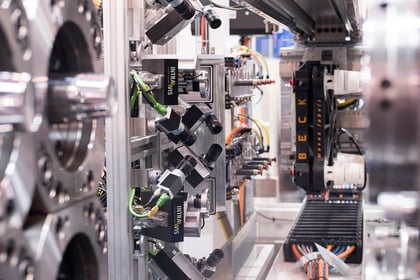

Meanwhile, at the Arburg Inc. booth (W3743), we will team up with their industry partners Arburg, Kebo, MCC Vertraete and Beck Automation to showcase an innovative production line tailored for the medical sector. It’s not just another typical solution for manufacturing medical tubes: It's a cutting-edge production process that leverages high-precision in-mold labeling for medical products. The impact of this innovative medical technology was demonstrated at the Fakuma trade show in Germany last October, highlighting how IML significantly enhances value within the medical industry.

Meanwhile, at the Arburg Inc. booth (W3743), we will team up with their industry partners Arburg, Kebo, MCC Vertraete and Beck Automation to showcase an innovative production line tailored for the medical sector. It’s not just another typical solution for manufacturing medical tubes: It's a cutting-edge production process that leverages high-precision in-mold labeling for medical products. The impact of this innovative medical technology was demonstrated at the Fakuma trade show in Germany last October, highlighting how IML significantly enhances value within the medical industry.

First and foremost, the single-stage process produces a completely finished part, leading to reduced transportation and processing costs. Additionally, it minimizes the risk of unhygienic factors. Furthermore, IML ensures authenticity, enabling unparalleled precision in positioning and consistent accuracy. In addition, the incorporation of RFID and temperature indicators in the label opens up exciting new avenues for tracking and tracing in supply chains. Finally, the use of the same plastics in the IML label and carrier simplifies recycling and promotes sustainability.

Our IMLWatcher inspection system utilizes four cameras and a special lighting technique to not only detect common IML defects extremely precisely, but also inspect the sealing surface and thread diameter. Overall, top-notch quality for medical products is ensured. Additionally, the seamless integration of the IMLWatcher into Beck Automation's robot handling results in significant space savings in the production hall.

Even more IML: Thorough quality assurance of 5 gallon IML pails

There is more excitement in the realm of in-mold label inspection at NPE. Over at the Milacron booth (W1601), a captivating production line for 5-gallon IML pails is showcased – a cooperation of Milacron, Beck Automation and INTRAVIS. Another IMLWatcher will not only inspects every detail of the in-mold label but the system will also check for short shots at the pail’s edges. Not stopping there, the system also conducts a thorough quality control inside the pail for defects such as blow-byes and contaminations.

There is more excitement in the realm of in-mold label inspection at NPE. Over at the Milacron booth (W1601), a captivating production line for 5-gallon IML pails is showcased – a cooperation of Milacron, Beck Automation and INTRAVIS. Another IMLWatcher will not only inspects every detail of the in-mold label but the system will also check for short shots at the pail’s edges. Not stopping there, the system also conducts a thorough quality control inside the pail for defects such as blow-byes and contaminations.

Stay Tuned: Preform Innovation Showcase at Husky Booth

So far, we have already unveiled several advancements in quality control for bottles and containers, closures as well as labeling. While the preform area remains a secret for now, visitors at NPE can anticipate an exciting exhibit at the booth of the partner Husky Technologies (W2801). “Up to now, we do not want to reveal too much. But I can promise an upcoming innovation for the preform production and quality control, with a strong emphasis on sustainability and circular economy.”, says Andreas Mueller, CEO of INTRAVIS Inc.

So far, we have already unveiled several advancements in quality control for bottles and containers, closures as well as labeling. While the preform area remains a secret for now, visitors at NPE can anticipate an exciting exhibit at the booth of the partner Husky Technologies (W2801). “Up to now, we do not want to reveal too much. But I can promise an upcoming innovation for the preform production and quality control, with a strong emphasis on sustainability and circular economy.”, says Andreas Mueller, CEO of INTRAVIS Inc.

NPE is just around the corner

As the curtain rises on NPE 2024, we invite you on a journey through the realm of inspection solutions and promises an enlightening experience. Join the INTRAVIS team as they redefine industry standards, one inspection at a time.

Interested in diving deeper into these innovative solutions? Explore more insights on our NPE webpage!