Part 2: How we moved to plastic packaging

On the occasion of our 30th company anniversary, we look back on the development of INTRAVIS in a 6-part series. We shed light on where it all began, why INTRAVIS is actually called INTRAVIS, what influence a student had on our start in the plastic packaging industry, and how a vision has always driven us for 30 years now. Today: In Part 2, we learn how INTRAVIS slipped into the niche of inspection systems for plastic packaging.

After INTRAVIS had successfully installed its first systems for inspecting sewing needles, Gerd Fuhrmann looked around to see in which industries the technologies used could also be applied, possibly in only slightly modified form.

INTRAVIS first came into contact with the plastics industry in 1995. In that year, we developed and manufactured a system for inspecting CD cases. The real catalyst for entering the plastics industry, however, was a conversation Gerd Fuhrmann had with a student who was writing his PhD thesis at our company: "His parents had a company that manufactured plastic foils. One day, he said to me that the plastics industry was currently the place that was particularly lucrative and where exciting new things were happening."

From this conversation, Gerd Fuhrmann sought contact with a nearby plant in Baesweiler. And indeed: The company described problems with flashes (material surplus) in its extrusion-blown packaging. Unfortunately, the project was not placed - such a high investment in an unknown technology; the headquarter did not go along with it.

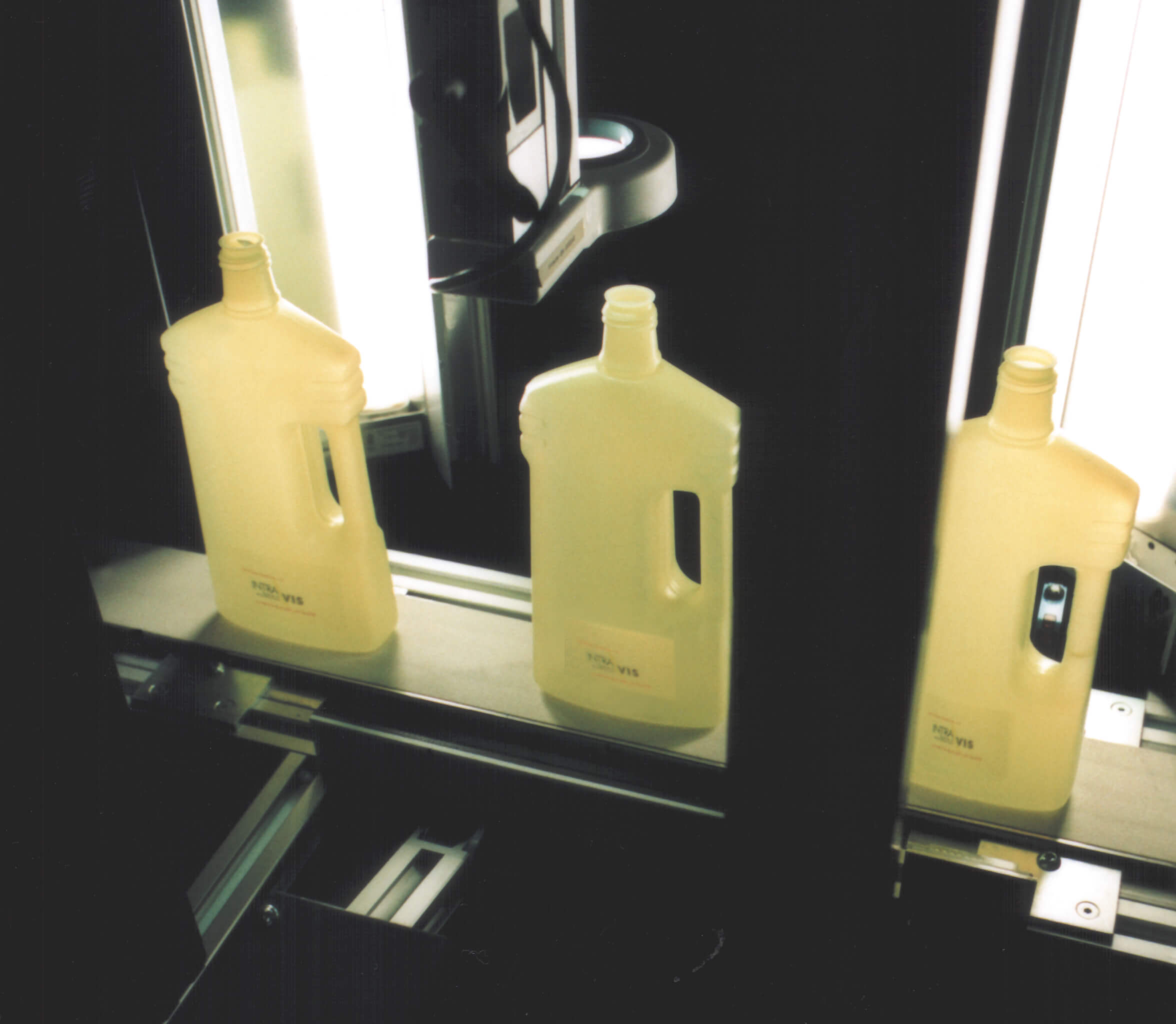

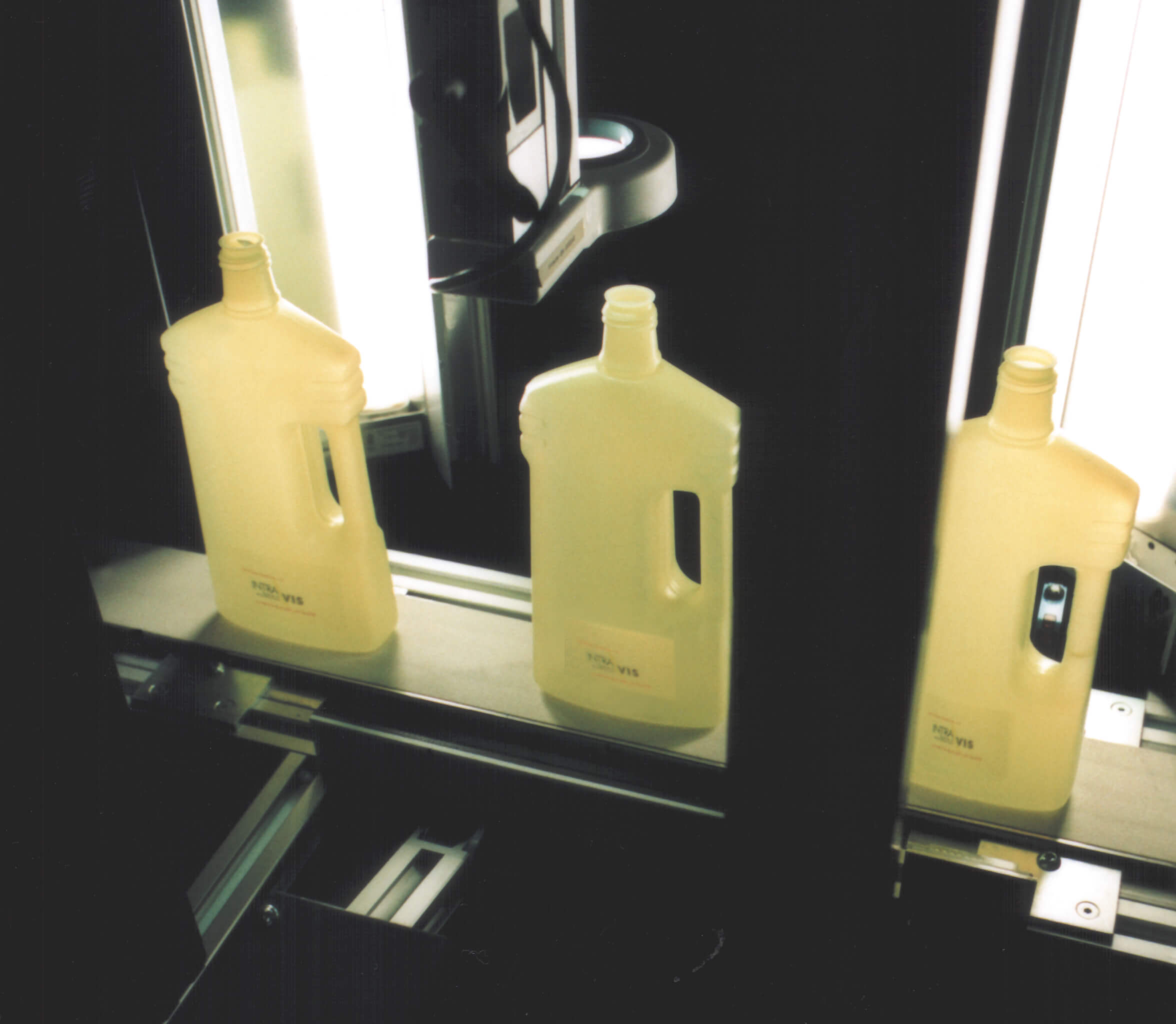

A short time later, INTRAVIS received an order to inspect the in-mold decoration of an extrusion-blown bottle. After this project was successfully implemented, we advertised our solutions in relevant trade journals. As a result, there was, among other things, a call from Switzerland, where a manufacturer of blow molding machines described problems with flashes and was looking for a solution to sort out defective products.

"And so I went to Switzerland and the manager of the plant described his problems to me in detail," Gerd Fuhrmann reports. He continues: "He was also impressed with our approach that the operator could 'teach' new products to be inspected without needing to have any knowledge of programming."

After a validation process, which took place in a production plant in France, we were able to convince the customer of our solution. Above all, the user-friendly concept, which still characterizes our systems today, was the clincher in our favor at that time.

At the end of the process, we received an order for incredible 50 AVI-1 systems. The order was handed over personally by Günther Lehner, CEO of ALPLA at that time. It was the starting signal for a spectacular rise in the "inspection of plastic packaging" market. And the Alpla plant in Baesweiler finally received its desired inspection systems.

In the next episode of our series, you will learn how INTRAVIS has continued to grow over the years and what the consequences were.

Click here for the first article in the series: The beginnings of INTRAVIS